Conventional saw blades struggle to make clean cuts in MDF, often resulting in rough edges and additional labor. Power hand saws generate excessive dust, so reconsider using them.

To tackle this, you’ll require a circular saw equipped with a sturdy, resilient blade that effortlessly slices through MDF without causing issues.

MDF, a composite material comprising wood fibers, resin, and wax, finds application in a wide range of products, from cabinets to countertops. Achieving precise cuts with this fiberboard can be challenging.

This is why having the best MDF saw blade becomes essential for those working with MDF. It ensures every cut is smooth, precise, and accurate.

In our selection of the top 5 Best Table Saw Blade For MDF, we’ll guide you in selecting the right saw blade for your specific needs. Along with information on the features of MDF cutting blades, we’ll also provide crucial insights about them shortly.

Top 5 Best Table Saw Blade For Mdf:

MDF, which stands for medium-density fiberboard, is a commonly used building material in the construction of cabinets, shelves, and various woodworking endeavors.

Although MDF is generally soft and manageable, achieving clean cuts in it can be a challenge. To ensure precision when working with MDF, the importance of a quality saw blade cannot be overstated. In this article, we’ll introduce you to five top-notch circular saw blades designed for cutting MDF.

Our Recommendations Best Table Saw Blade For Mdf

| Image | Product | Details | Price |

|---|---|---|---|

|

DEWALT (DW3106P5) 10-Inch Miter / Table Saw Blades-Best Overall | Excellent for working with hardwood They produce minimal debris while cutting. |

Check Price |

|

DEWALT (DW3219PT) 10-Inch Miter / Table Saw Blade | Resists heat and corrosion, extending the blade’s lifespan. It’s balanced for precise and accurate cuts. |

Check Price |

|

Freud D0760X Diablo Ultra Finish Saw Blade | This blade makes quick and smooth cuts on various materials. Its thin kerf design reduces waste material. |

Check Price |

1)DEWALT (DW3106P5) 10-Inch Miter / Table Saw Blades-Best Overall:

If you’re in search of a top-quality saw blade for cutting MDF, look no further than the DEWALT DW3106P5. This is a combo package, offering two saw blades in one.

It includes a 32-tooth blade designed for general use and a 60-tooth blade tailored for achieving fine finishing results. The DEWALT DW3106P5 is versatile and up to the task when it comes to miter saw and slide miter saw projects. It stands out with its slim-kerf design, ensuring swift, clean cuts that leave behind minimal debris.

What’s more, each blade tip is reinforced with additional steel, enhancing precision and strength. With the DEWALT DW3106P5, you can confidently make ultra-fine crosscuts without concerns about damaging your materials.

The DEWALT DW3106P5 features a built-in computer-balanced plate that reduces vibrations during the cutting process. This balance provides better control, ensuring precise positioning of the blade on your delicate material and resulting in accurate and fine crosscuts.

Furthermore, the DW3106P5 comes equipped with an anti-stick coating, offering resistance to heat and corrosion. This extends the lifespan of the blades, making them ideal for slide miter saw and miter saw tasks.

Pros:

- These blades are excellent for working with hardwood, softwood, chipboard, and even plywood.

- They consistently deliver precise and uniform cuts with each use.

- They produce minimal debris while cutting.

Cons:

- These blades are primarily designed for miter saws and should not be swapped with any other saw.

- Certain users report that the blades tend to lose sharpness relatively fast.

- Some users assert that these blades can lead to splintering on the back side of cuts.

2)DEWALT (DW3219PT) 10-Inch Miter / Table Saw Blade:

Crafted from top-quality micro-grain carbide, the DEWALT DW3219PT features highly sharp cutting edges that effectively minimize the splintering of materials.

It boasts a precisely balanced laser-cut body, contributing to outstanding cutting performance. Furthermore, it includes unique dampening slots that decrease vibrations, thereby improving cutting precision.

This versatile blade is suitable for a range of materials, with a notable ability to excel in cutting MDF and similar substances. Additionally, it incorporates a robust coat finish that reduces friction, heat, and gum buildup, significantly extending the blade’s lifespan.

The DEWALT DW3219PT stands out due to its premium micro-grain carbide composition, ensuring sharpness and minimizing splintering. Its precisely balanced laser-cut body enhances cutting precision, and the inclusion of dampening slots reduces vibrations, ensuring accuracy.

While this blade can handle various materials, it excels in cutting MDF and similar substances. Its durable coat finish reduces friction, heat, and gum buildup, resulting in an extended blade lifespan. This makes it a top choice for those seeking consistent, high-quality cuts and longevity in their saw blade.

Pros:

- the blade has sharp edges for clean cuts, reducing splintering.

- It’s balanced for precise and accurate cuts.

- A built-in computer-balanced plate minimizes vibrations, enhancing control.

- Resists heat and corrosion, extending the blade’s lifespan.

Cons:

- Best for miter saws, not interchangeable with other saw types.

- Some users found them dull quickly.

- Reports of potential backside splintering.

3)Freud D0760X Diablo Ultra Finish Saw Blade:

The Freud D0760X possesses a 7-1/4-inch diameter and is armed with 60 sharp teeth. This design enables swift and smooth cutting through various materials.

The blade is constructed using exclusive TiCo high-density carbide, making it ideal for crosscutting tasks. Its remarkably thin kerf design ensures efficient and rapid cutting with minimal waste.

In addition to the ultra-thin kerf, it incorporates an anti-vibration feature that reduces operational noise and enhances the blade’s lifespan. The blade’s steel body is laser-cut to provide a smooth and flat-cutting experience.

Moreover, it boasts a Perma-shield non-stick coating that minimizes friction and heat buildup, significantly prolonging the blade’s longevity.

The Freud D0760X boasts a 7-1/4-inch diameter and is fitted with 60 teeth, facilitating quick and smooth cutting across various materials.

Crafted with exclusive TiCo high-density carbide, this blade is optimized for crosscutting tasks. Its ultra-thin kerf design ensures efficient, low-waste cutting.

Beyond the thin kerf, it incorporates an anti-vibration feature, minimizing operational noise and increasing the blade’s lifespan. The laser-cut steel body guarantees smooth and flat cuts. Furthermore, the Perma-shield non-stick coating reduces friction and heat buildup, contributing to an extended blade lifespan.

This blade’s 7-1/4-inch diameter and 60 teeth enable rapid and smooth cutting. Constructed with TiCo high-density carbide, it excels in crosscutting tasks. The ultra-thin kerf design ensures efficient cutting with minimal waste.

The anti-vibration feature reduces operational noise and enhances the blade’s durability. Laser-cut steel body ensures smooth, flat cuts.

The Perma-shield non-stick coating reduces friction and heat buildup, significantly extending the blade’s lifespan. This blade is a good choice for those seeking fast, efficient cutting and a longer-lasting performance.

Pros:

- This blade makes quick and smooth cuts on various materials.

- Its thin kerf design reduces waste material.

- The anti-vibration feature lowers noise and extends the blade’s life.

- Ideal for precise crosscuts in softwood and hardwood.

- Smoothens work surfaces for a high-quality finish.

- Precision-balanced blade for accurate cuts even under heavy loads.

Cons:

- Limited to specific saw types and material thickness.

- Some users reported the blades dulling relatively quickly.

- There have been claims of possible backside splintering during cuts.

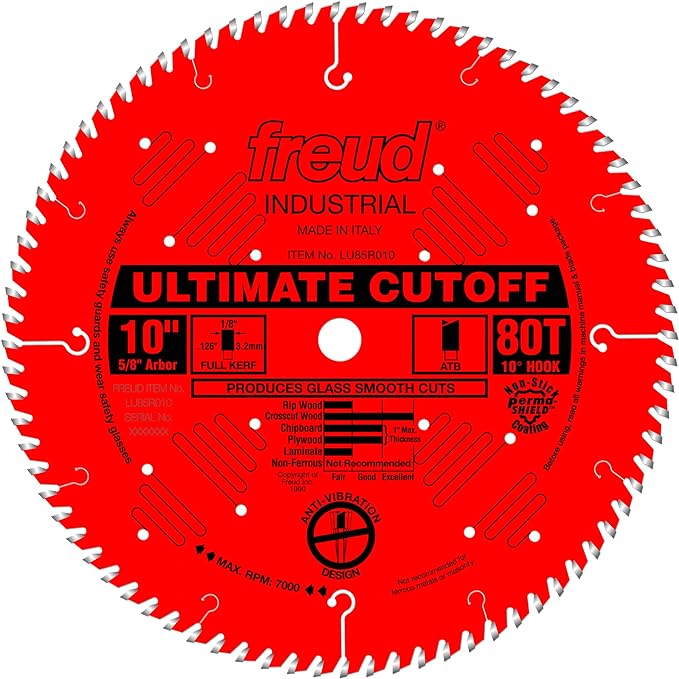

4)Freud LU85R010: 10″ Carbide Tipped Saw Blade:

The Freud LU85R010 is equipped with an 80-tooth cut-off blade, featuring an alternating-top-bevel (ATB) configuration. Its teeth are strategically arranged, facing both left and right, making it a versatile choice for crosscutting softwood, hardwood, and general use.

What sets the LU85R010 apart is its unique side grind, which enhances the smoothness of work surfaces as it cuts through them. This results in excellent smoothness and a high-quality finish in your work.

Designed for exceptional performance, the Freud LU85R010 is ideal for crosscutting wood with thickness ranging from 1/4 to 1-5/8 inches.

It also excels at cutting plywood and chipboard less than one inch thick, making it a versatile choice for your projects. Additionally, it’s well-suited for ripping wood and laminate when working with materials of the ideal thickness.

The precision-balanced blade, pre-tensioned for optimal performance even under heavy loads, is a standout feature of the LU85R010. It also incorporates anti-vibration slots to reduce chatter, resulting in a longer blade life and a cleaner finish in your projects.

Pros:

- Perfect for crosscutting in wood and sheet materials.

- Smoothens work surfaces for high-quality, smooth finishes.

- Suitable for a range of material thicknesses and types.

- Provides precise cuts even under heavy loads.

- Reduces vibrations for cleaner cuts and longer blade life.

Cons:

- Mainly for crosscuts and not suitable for all types of saws or materials.

- Some users reported potential splintering issues on the back side of cuts.

- Not Ideal for Thick Materials

5)Diablo by Freud “Freud D1050X Diablo 10” 50-tooth ATB Combo Saw Blade:

The Diablo D1050X excels in ripping and crosscutting hardwood, softwood, and sheet materials, making it particularly effective with manmade materials like MDF. Its versatile design allows it to perform exceptionally on a wide range of materials.

Constructed from robust materials, the Diablo D1050X features a steel plate and high-density carbide tips, ensuring its reliability and long-lasting performance.

This blade is user-friendly, featuring a precise Kerf Laser-precision design that enables laser-precision cuts. Its precise design offers excellent control over blade positioning and smooth feeding, allowing for maximum precision in your cuts.

The Perma-shield non-stick coating shields the blade from gumming, heat, and corrosion. The shock-resistant brazing with a tri-metal feature equips the carbide tips to withstand intense heat.

With a hardened steel body, it delivers a longer lifespan and a dependable cutting edge. Expansion slots ensure the blade expands to maintain straight and accurate cuts. Furthermore, the titanium carbide with micrograin makes this blade exceptionally durable.

Pros:

- Suitable for hardwood, softwood, and various sheet materials.

- Enables fast and efficient cuts with minimal waste.

- Reduces noise and extends blade life.

- Resists heat and corrosion for prolonged durability.

- Provides control and precision with laser-precision design.

Cons:

- Best used with miter saws, not for all types of saws.

- Some users report blades may become dull relatively quickly.

- Claims of potential splintering on the backside of cuts.

Buying Guide, What to Consider When Buying the Best Table Saw Blade for Mdf:

MDF, a versatile material, is created by mixing sawdust and glue under heat and pressure. It ranges in thickness from 1/4 inch to 1 inch and is engineered from hardwood or softwood residuals, transformed into wood fibers using a defibrillator.

These fibers are combined with resin or wax and shaped into panels through intense pressure and heat, resulting in denser MDF compared to wood or particleboard.

When cutting MDF, it’s crucial to note the safety risks involved. Cutting it can dull a table saw blade that lacks tungsten carbide and generates a lot of dust, potentially harmful to health. MDF also contains formaldehyde resins, which can pose health risks.

While any wood-cutting tool can handle MDF, understanding these unique MDF characteristics is vital for achieving optimal cutting results.

When cutting MDF for the first time, it’s crucial to select the right blade. Keep in mind that table saw blades vary in size and construction.

Understanding these key considerations is important when choosing the best blade for MDF cutting.

Selecting the Right Blade Size for MDF Cutting:

Most table saw blades have a 10-inch diameter, although some may vary in size. It’s advisable to choose a slightly smaller blade compared to the maximum capacity of your saw when working with MDF. Never attempt to use a larger blade than your saw can handle.

Choosing the Appropriate Blade Teeth Count for MDF:

The Teeth Per Inch (TPI) indicates the number of teeth on the blade. MDF is denser than regular boards, so selecting the correct TPI is essential. The recommended tooth count for MDF cutting typically ranges from 50 to 80 teeth, as blades with more teeth perform better on denser materials. For cutting thinner materials, a 60-tooth composite blade is more suitable.

Types of Blades for MDF Cutting:

When deciding on a table saw blade for MDF cutting, you’ll encounter four blade options to choose from:

Crosscut Blade:

These blades have a tooth count ranging from 80 to 90 and are well-suited for cutting across the grain of the material. They provide precise results but produce more sawdust, which may pose health risks.

Combination Blade:

The combination blade is a versatile 10-inch option with tooth counts typically ranging from 32 to 50. It can handle various tasks, including ripping and crosscutting.

It’s a suitable choice, especially for beginners, and can work with a variety of materials like plywood, hardwood, softwood, MDF, pressure-treated lumbers, and wood beams. This blade is also great for making precise cuts on lumber pieces and lightweight materials, including MDF.

Multi-Purpose Blade:

Also known as a versatile blade, the multi-purpose blade features 60 teeth and is specifically designed for cutting engineered materials like MDF. This blade can both ripping and crosscutting and offers a higher TPI than the combination blade. It excels particularly in cutting MDF.

The multi-purpose blade is perfect for creating intricate cuts in MDF, whether you’re crafting or repairing furniture. It’s also suitable for making lengthy cuts in layered plywood and similar materials, as well as precise and delicate crosscuts on MDF.

Alternate-Top-Bevel (ATB) Blade:

The ATB blade is highly effective when cutting dense materials like melamine, MDF, hardboard, and particleboard. These materials pose a challenge due to their density, which can wear down the blade tips over time.

If you have multiple ATB blades or don’t mind frequent sharpening, this blade is suitable for working with tougher materials. However, for consistent use on denser materials, it’s advisable to opt for a Triple-Chip Grind (TCG) blade.

Rust-Resistant Coating:

When purchasing a circular saw blade, it’s important to consider its rust-resistant coating. This is crucial because the saw blade will be exposed to moisture and humidity, which can lead to rusting. You can determine the presence of a rust-resistant coating through various means.

One method is to check the manufacturer’s website, where you should find information about the blade’s rust-resistant features. Another approach is to read reviews about the saw blade. For maximum corrosion resistance, opt for a blade with an electroplated coating.

Featherweight and Sturdy:

Opting for a lightweight blade is essential as it reduces fatigue during use and minimizes the risk of binding while cutting.

Choosing a sturdy blade contributes to the longevity of your saw. Even during demanding cuts, a durable blade will remain intact without chipping or breaking. Such blades also maintain their sharpness over time. By seeking a lightweight and robust blade, you can ensure the longevity of your saw.

Tooth Count:

The quantity of teeth on a blade directly impacts the smoothness of your cuts. More teeth on a blade translate to a finer cut, but it also demands more power to spin and may generate additional heat. Therefore, selecting the right blade with the appropriate tooth count for your material and cutting type is crucial.

For general-purpose cutting, a blade with 24 to 36 teeth is highly suitable. If you’re dealing with specialized applications like plywood or chipboard, opt for a blade featuring 50 to 80 teeth to achieve a smoother and more precise cut. Finding the right balance in tooth count ensures your cutting needs are met effectively and efficiently.

Bottom Line:

As mentioned previously, MDF stands out as a versatile material with greater density compared to regular wood. To ensure a safe and effective cutting process, it’s essential to have a good understanding of this material.

By keeping in mind the tips and precautions outlined earlier when working with MDF, you can achieve superior cutting results and minimize risks.

It’s equally important to be well-informed about the most suitable blade choices for MDF cutting, which will contribute to an improved cutting experience and outstanding outcomes. This knowledge ensures that you’re well-prepared to work with MDF and achieve precision and safety in your woodworking projects.

FAQs: Best Table Saw Blade For MDF

Is a Mask Required for Cutting MDF?

When cutting MDF, it’s important to recognize that it produces a substantial amount of fine dust, which poses health risks if inhaled. To safeguard your health, using a respirator equipped with HEPA filters is crucial.

A basic dust mask will only offer adequate protection against the minuscule MDF particles, which can swiftly spread throughout your surroundings, including your clothing and hair, if proper precautions are addressed.

Wearing a respirator, operating in a well-ventilated area, and diligently cleaning up MDF dust using a damp cloth or vacuum are essential steps. By adhering to these safety measures, you can work with MDF without inhaling its potentially harmful dust.

Is it Possible to Cut MDF Using a Jigsaw?

While jigsaws aren’t the optimal choice for cutting MDF compared to circular blade saws, they can get the job done with some care. The key consideration is the blade’s tooth count; more teeth reduce the risk of chipping the material during the cut.

For cleaner results, it’s advisable to use a fine-toothed blade. When using a jigsaw or cordless saw for cutting MDF, proceed slowly and steadily to prevent chipping or damaging the material. With a little patience, you can achieve precise and clean cuts with your jigsaw.

Do You Need a Mask to Cut MDF?

MDF also produces a substantial amount of fine dust during cutting, posing inhalation hazards. Thus, it’s vital to use a respirator equipped with HEPA filters when cutting MDF.

A basic dust mask doesn’t provide sufficient protection against the minuscule MDF particles, which can quickly spread to your clothes, hair, and entire workspace if not handled with proper precautions.

Wearing a respirator, working in a well-ventilated area, and diligently cleaning up MDF dust with a damp cloth or vacuum are essential measures to ensure safety and avoid inhaling harmful dust while working with MDF.

Is an MDF Saw Blade a Good Investment?

Absolutely, yes. An MDF saw blade is a specialized blade explicitly designed for cutting MDF. These blades are typically crafted from high-quality materials and feature sharp cutting edges, making them exceptionally well-suited for clean and efficient MDF cutting.

While MDF saw blades might have a higher upfront cost compared to standard blades, they are a worthwhile investment, especially if you frequently work with MDF. These blades not only simplify your work but also help prevent material damage.

Related Posts:

- How To Sharpen Table Saw Blades

- Best Table Saw Blades Reviewed

- How Thick is a Table Saw Blade

- How To Clean Table Saw Blade?

- How to Change a Table Saw Blade?: (All Methods and Models)

- Why Does My Table Saw Blade Wobble? And (How To Fix)

- How Many Teeth For Table Saw Blade

- Are Table Saw Blades Reverse Threaded

- 24 vs 40 Tooth Saw Blade

- 40 Tooth vs 60 Tooth Saw Blade